What Is the Core Working Principle of a 10HP Micro-Oil Twin Screw Single Stage Compressor?

Overview of the Product Structure and Operating Foundation

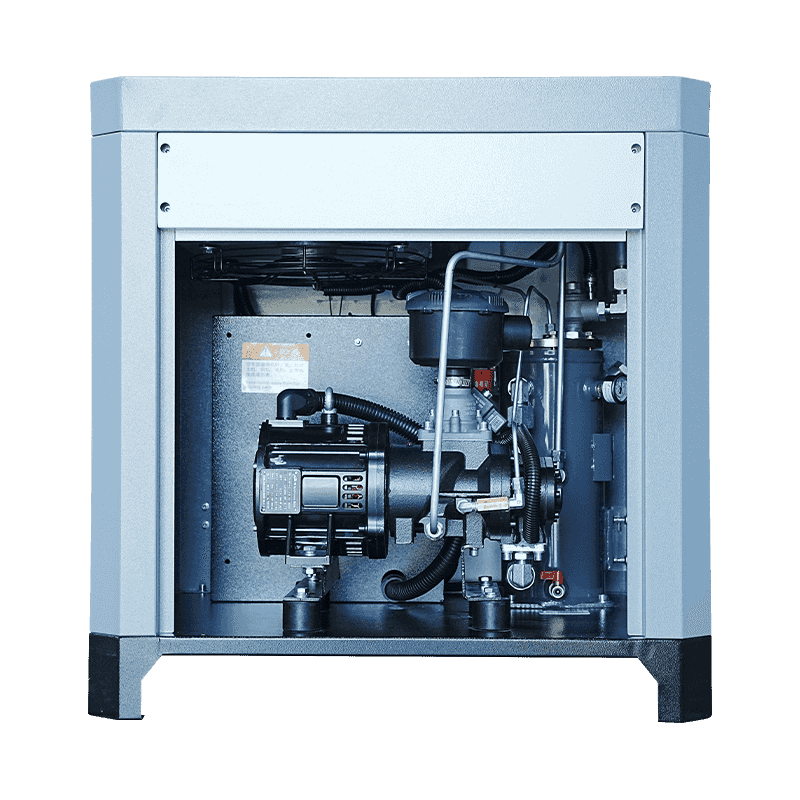

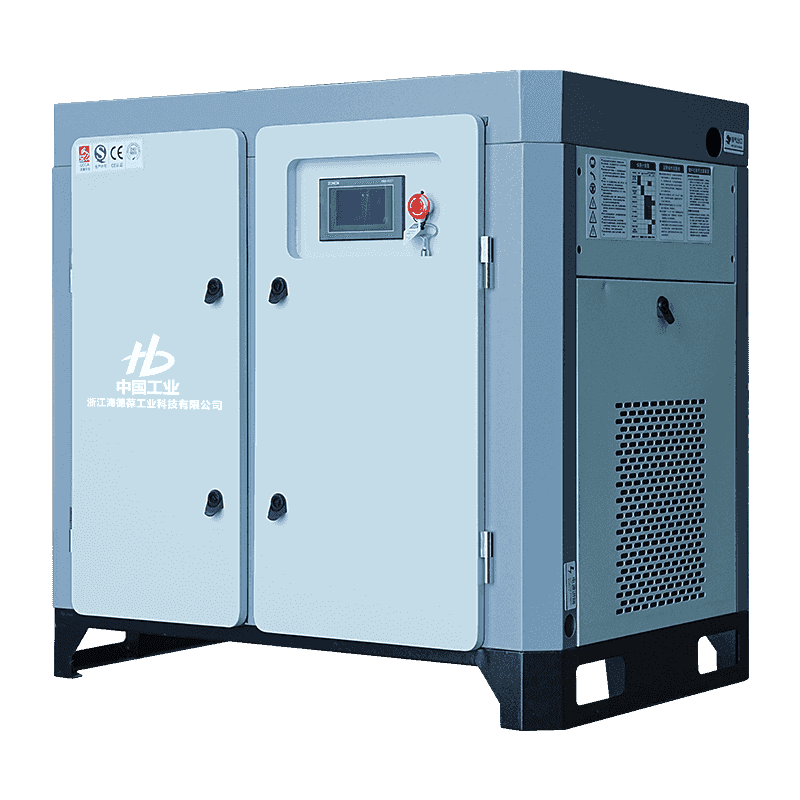

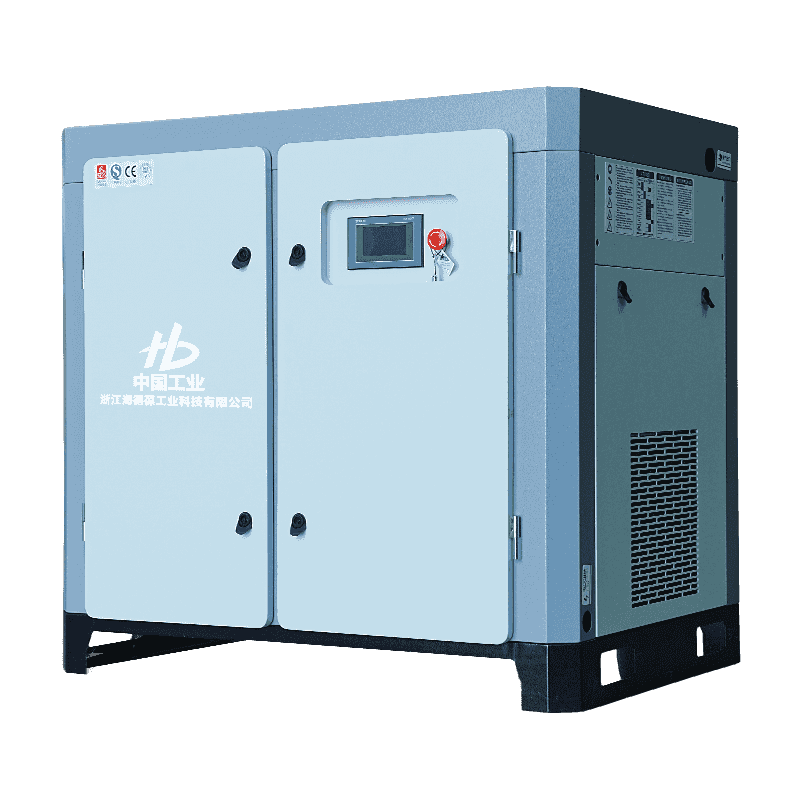

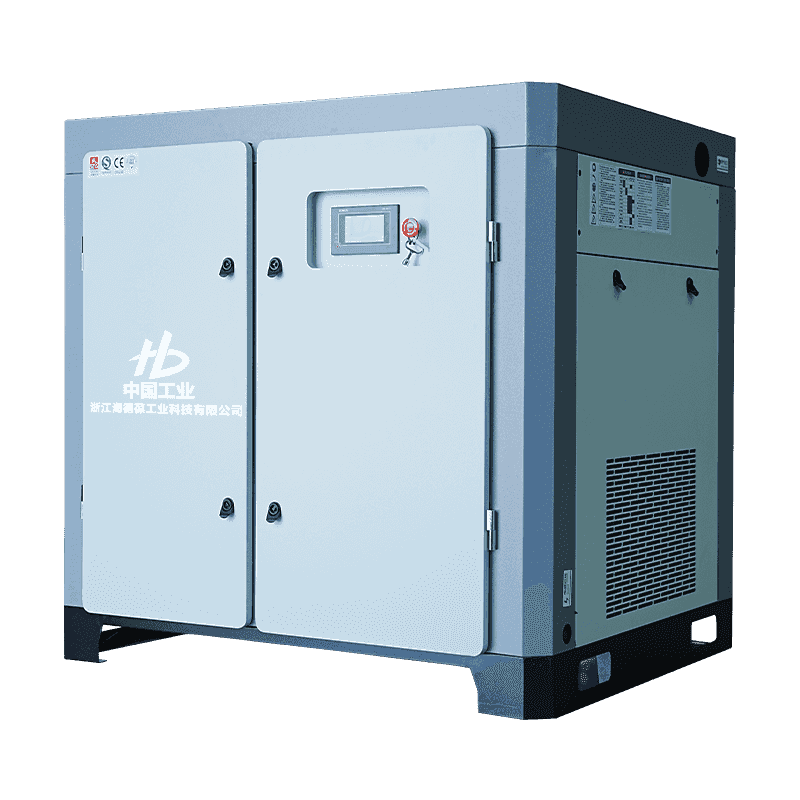

The core working principle of a 10HP micro-oil twin screw single stage compressor is based on the coordinated motion of a pair of intermeshing rotors that compress air through continuous volume reduction. Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, is a professional manufacturer and supplier of this type of industrial compressor. By integrating a micro-oil lubrication system, oil-cooled permanent magnet synchronous motor and optimized cooling structure, the equipment enables reliable and stable compressed air output suitable for industries such as pharmaceuticals and food processing where stable air sources are required. The micro-oil design ensures that the oil not only lubricates the rotors but also contributes to sealing and cooling, enabling the compressor to operate efficiently under a single-stage compression mechanism.

Compression Mechanism Based on Intermeshing Twin Screws

The heart of the compressor lies in the twin screw airend. Inside the compression chamber, a male and female rotor rotate in opposite directions. As the rotors begin to mesh, the air drawn from the inlet is trapped between the rotor lobes and the casing. This trapped air volume gradually decreases as the rotors continue turning, leading to continuous compression. Because of the micro-oil injection, the compression efficiency is enhanced by reducing leakage and improving thermal stability. Zhejiang Haidebao Industrial Technology Co., Ltd. utilizes high-precision machining for the rotor profiles, ensuring smooth intermeshing and reducing mechanical losses during operation. The single-stage configuration compresses the air directly to the target pressure in one continuous process, streamlining the internal power flow and supporting long-term industrial application scenarios.

Role of the Micro-Oil Lubrication and Oil Separation System

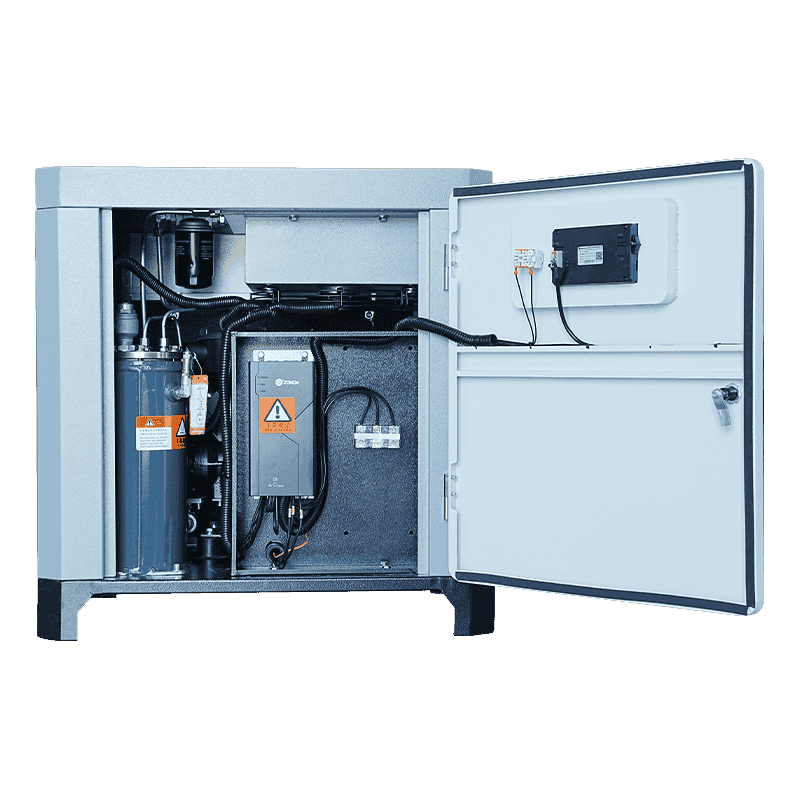

Micro-oil technology plays a significant role in the performance of this 10HP compressor. During compression, a measured amount of lubricant is injected into the chamber to assist in sealing rotor clearances, removing heat generated by compression and reducing friction between metal surfaces. Zhejiang Haidebao Industrial Technology Co., Ltd. equips its compressors with a low-pressure special oil separation system that includes internal baffles, an enlarged oil separation barrel and oversized oil separation cores. These components work together to maintain exhaust oil content below 3 ppm, enabling reduced oil consumption and improved operating stability. After carrying heat away from the compression chamber, the oil is separated effectively before being cycled back into the system.

| System Component |

Main Function |

Impact on Operation |

| Micro-oil injection |

Lubrication, sealing and cooling |

Improves efficiency and thermal balance |

| Oil separation barrel |

Primary oil-air separation |

Helps maintain low exhaust oil content |

| Oil separation core |

Fine separation of lubricant |

Reduces oil carryover and lowers oil consumption |

Cooling System Designed for High Ambient Temperatures

To maintain stable operational temperature, the compressor integrates a cooling system designed to perform under ambient temperatures up to 46°C. Zhejiang Haidebao Industrial Technology Co., Ltd. utilizes a specialized coolant that flows through the system to ensure rapid heat dissipation, particularly for lubricating oil that absorbs thermal load from the compression cycle. The cooling system configuration supports sustained operation even in demanding industrial environments. By cooling the lubricant efficiently, the compressor minimizes thermal expansion, maintains rotor clearance stability and upholds consistent compression efficiency. This temperature-adapted design allows the equipment to withstand continuous operation, making it suitable for facilities requiring round-the-clock air supply.

Oil-Cooled Permanent Magnet Synchronous Motor Drive

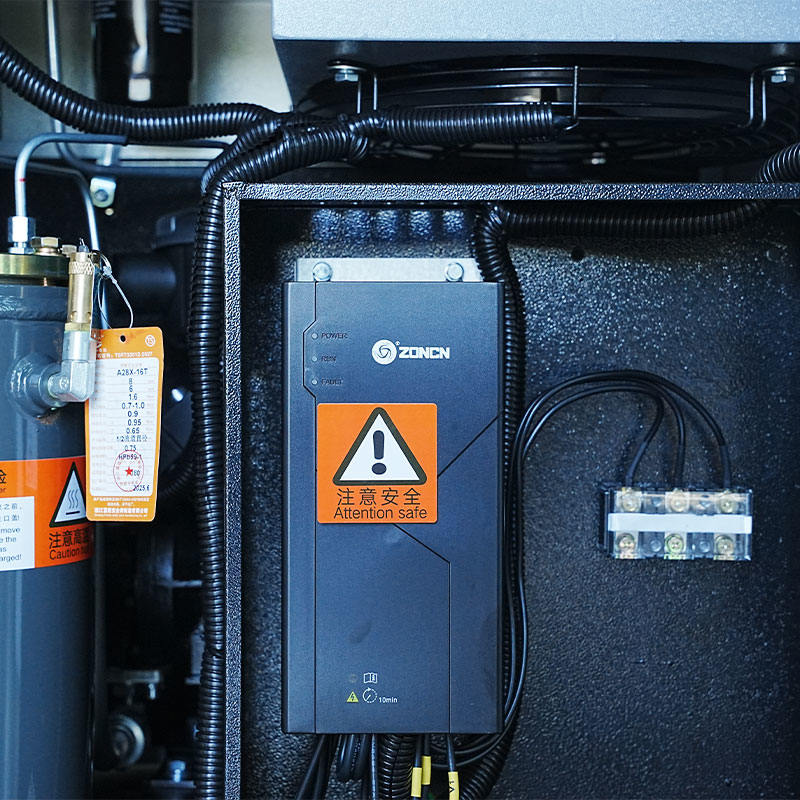

The motor powering the compressor is an oil-cooled permanent magnet synchronous motor, equipped with high-quality permanent magnets. One of its characteristics is the absence of rotor excitation current, which helps maintain stable efficiency throughout the operating range. Compared with traditional asynchronous motors, the starting current of this motor type is lower, reducing electrical impact on the power grid during start-up. The motor's cooling circuit uses the same micro-oil system, enabling direct heat removal from the rotor and stator surfaces. This helps prevent overheating, supports longer service life and ensures reliability during heavy industrial use. The constant efficiency and steady power factor make the motor and airend combination highly suitable for stable compressed air production.

| Motor Feature |

Description |

Operational Benefit |

| Permanent magnet rotor |

No excitation current required |

Stable efficiency across load ranges |

| Oil-cooled design |

Direct heat removal from motor |

Improved thermal management |

| Low starting current |

Less impact on the power grid |

Reduced electrical burden during start-up |

Industrial Application and Air Supply Stability

The principles behind the 10HP micro-oil twin screw single stage compressor allow it to deliver consistent compressed air suitable for numerous industrial applications. Zhejiang Haidebao Industrial Technology Co., Ltd. ensures that the overall system operates smoothly by integrating a stable airend, efficient oil separation design and a cooling mechanism capable of managing high operational demands. Industries such as pharmaceuticals and food processing rely on compressors that can provide uninterrupted air pressure without pressure fluctuations. The single-stage micro-oil compression structure provides such stability, making it a dependable choice for environments where production continuity and air quality are essential. By combining stable mechanical operation with controlled lubricant management, the compressor supports long-term industrial use in facilities requiring reliable compressed air delivery.

How Does the Energy Efficiency of a 10HP Micro-Oil Twin Screw Single-Stage Compressor Change Under Full Load and Unload Conditions?

Overview of Load Conditions and Energy Performance

A 10HP micro-oil twin screw single-stage compressor exhibits different energy efficiency characteristics when operating under full load and unload conditions. These variations are closely related to its mechanical structure, motor characteristics and oil management system. Zhejiang Haidebao Industrial Technology Co., Ltd., located in Quzhou City, Zhejiang Province, manufactures this type of compressor with an emphasis on stable performance and steady energy consumption patterns. The compressor adopts an oil-cooled permanent magnet synchronous motor, micro-oil lubrication system and a cooling design suitable for environments up to 46°C. These elements jointly influence how efficiently the compressor consumes power when the load fluctuates between full operation and unload states. Understanding these behaviors provides insights into system performance, operational cost and application suitability in industries such as pharmaceuticals and food processing that rely on continuous compressed air supply.

Energy Consumption Behavior Under Full Load Operation

Under full load, the 10HP micro-oil twin screw single-stage compressor operates at its designed capacity, delivering stable airflow with consistent pressure. During this stage, the permanent magnet synchronous motor runs with a near-constant power factor and efficiency, as the rotor contains high-quality permanent magnets and does not require excitation current. This contributes to reduced electrical losses and steady energy use. The intermeshing screws compress air continuously, while the micro-oil lubrication system ensures sealing and thermal balance. Zhejiang Haidebao Industrial Technology Co., Ltd. optimizes the airend and cooling components to maintain stable temperature even at high loads, which supports long-term operation without sudden efficiency drops. Because mechanical, electrical and thermal components work in coordinated alignment at full load, the compressor’s energy efficiency remains consistent, reflecting predictable power consumption.

| Operating Condition |

Energy Behavior |

System Response |

| Full load |

Stable and predictable energy use |

Motor and airend operate at designed efficiency |

| High temperature environment |

Cooling system stabilizes thermal load |

Performance remains consistent due to coolant design |

Energy Efficiency Characteristics During Unload Operation

When the compressor enters the unload state, the demand for compressed air is reduced, and the system stops compressing air while the motor continues running. Although the airend no longer performs compression, certain components still consume energy. The oil-cooled motor maintains rotation at low power to support rapid return to load when required. In this period, energy efficiency decreases because the compressor is not producing compressed air while still consuming electricity for mechanical movement and lubrication circulation. Zhejiang Haidebao Industrial Technology Co., Ltd. designs its compressors to minimize unnecessary power draw during unload, but energy consumption remains higher compared to the volume of air produced due to the absence of an active compression process. The oil separation system, though not under full load, still operates as part of the circulation cycle, contributing slightly to energy use.

| Unload Factor |

Description |

Effect on Efficiency |

| Motor still rotating |

Consumes energy without producing air |

Efficiency decreases |

| Oil circulation |

Maintains lubrication and cooling |

Contributes to energy use |

Influence of Permanent Magnet Synchronous Motor on Efficiency Stability

The use of an oil-cooled permanent magnet synchronous motor by Zhejiang Haidebao Industrial Technology Co., Ltd. helps maintain stable performance across different load conditions. Unlike traditional motors, the rotor in this design does not need excitation current, which allows its efficiency and power factor to remain constant regardless of load. This means that even under unload conditions, the fundamental electrical behavior of the motor stays stable. However, the mechanical output no longer converts energy into compressed air, leading to reduced operational efficiency despite stable internal motor efficiency. The lower starting current also reduces the electrical impact when transitioning between unload and full load states, supporting smoother operation in industrial environments.

Cooling and Oil Separation Systems and Their Effect on Energy Behavior

Cooling and oil separation components play key roles in determining energy performance under varying loads. Since the system is designed with an ambient temperature limit of 46°C and uses a special coolant, heat is managed effectively at full load, supporting stable compression efficiency. The oil separation system, consisting of internal baffles, a large separation barrel and oversized separation cores, helps maintain exhaust oil content below 3PPM. This reduces oil loss and prolongs maintenance intervals. During unload stages, these systems continue to operate at partial capacity to maintain readiness for immediate load response. Although they consume less power than during full load, they still contribute to overall energy use and thus lower operational efficiency in unload conditions.

Comparison of Full Load and Unload Energy Efficiency

The most significant distinction between full load and unload operation lies in the ratio of energy input to effective compressed air output. At full load, nearly all consumed energy contributes to producing compressed air, aligning electrical consumption with mechanical output. During unload, the compressor maintains rotation and circulation without generating compressed air, resulting in lower overall efficiency. Zhejiang Haidebao Industrial Technology Co., Ltd.’s design helps reduce unnecessary unload consumption, but the inherent characteristics of unload operation still affect performance. This difference is a fundamental aspect of screw compressor behavior and must be considered when selecting equipment for processes with variable air demand.

| Condition |

Energy Input |

Air Output |

Efficiency Level |

| Full load |

High but steady |

Maximum |

Higher efficiency |

| Unload |

Moderate |

Minimal |

Lower efficiency |

English

English Español

Español عربى

عربى